A poorly designed process leads to bad data getting sent to the client.

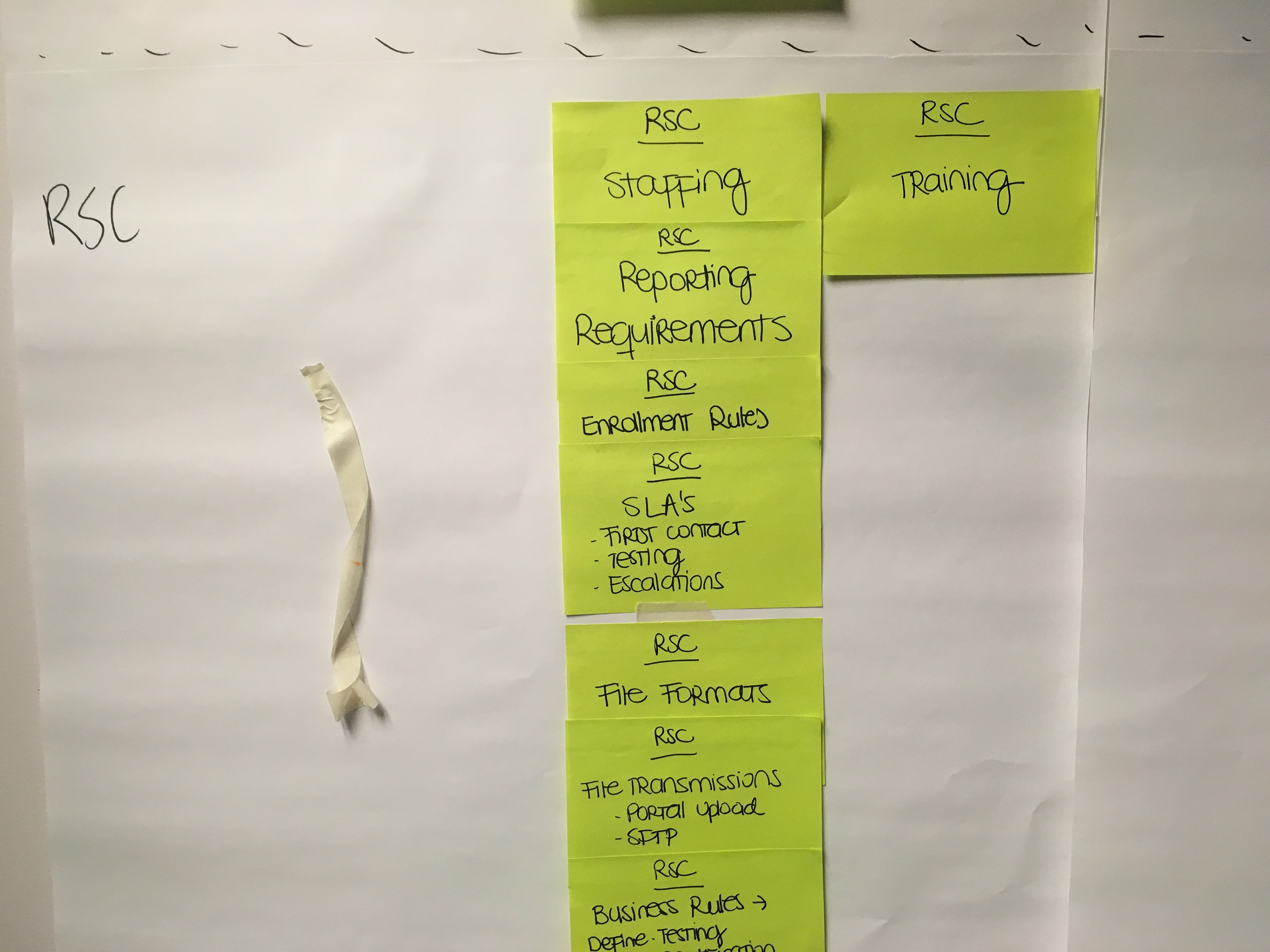

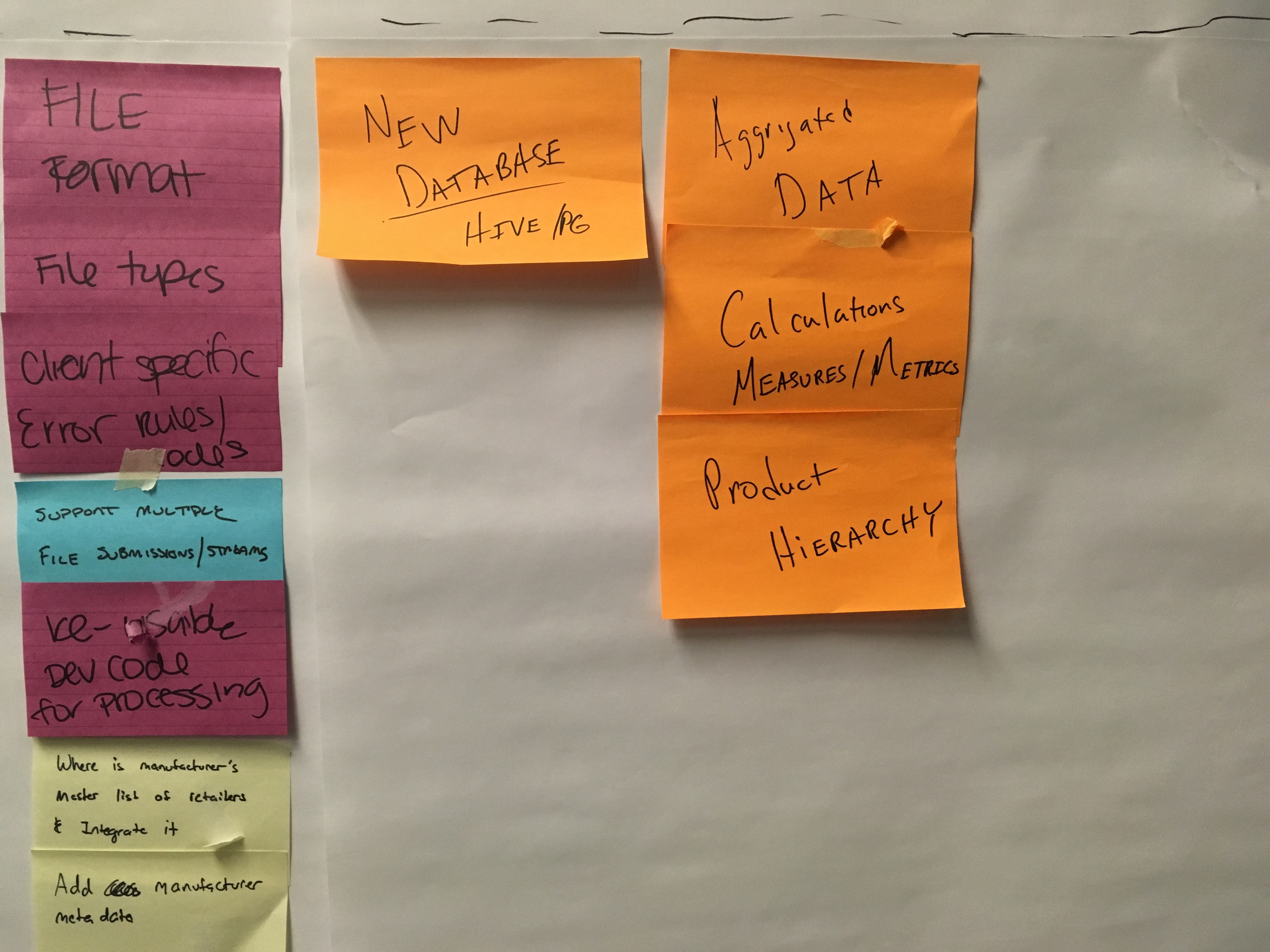

Both the file certification and the data validation checks for a data files submitted by retailers were manually completed. An RSC Rep was responsible for completing the file certifications, which meant manually viewing the submitted file and working with the retailer and potentially a client representative to alleviate any problems including data quality and format issues. Certification only had to occur for the initial data submission. After that, all the data quality checks got handled by the business analyst (BA). The BA would look at every submission. If there were any issues they would have to work with a client representative who would reach out to the retailer. After a submission was validated, the BA would have to inform an engineer that the data could get sent to the client. These processes didn’t work well, and a lot of poor quality data was getting sent to the client.

The issue was that after certification the data would automatically be released to the matching system. Certification only happened for the initial submission; this meant every submission afterward would be automatically released to matching. This lead to a lot of bad data getting into the matching system, and it created more work for the BA who had to try and fix it after the fact.

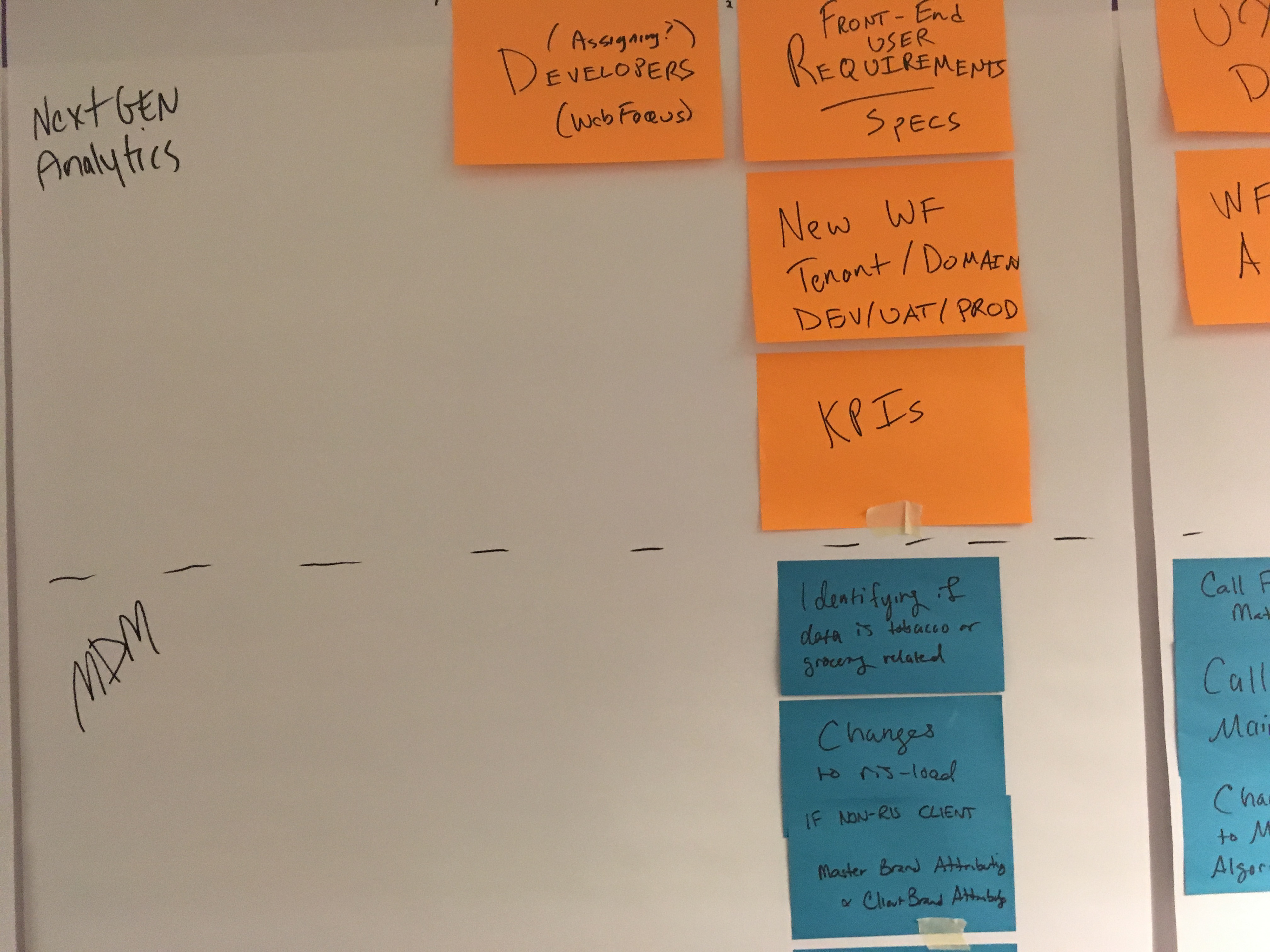

Adding more manual work would not solve the problem. Automation was needed.

The proposed solution for fixing the release of bad data into matching was to add a second manual check for the RSC rep. The second part was to create a BA user account, so they didn’t have to reach out the engineer anymore and could say the submission was ready for release through the RSC. The new check for the RSC rep would mean having to review every submission, which would increase their workload to an unmanageable point. Both of these solutions to would require a lot of development, and they were still highly error prone.

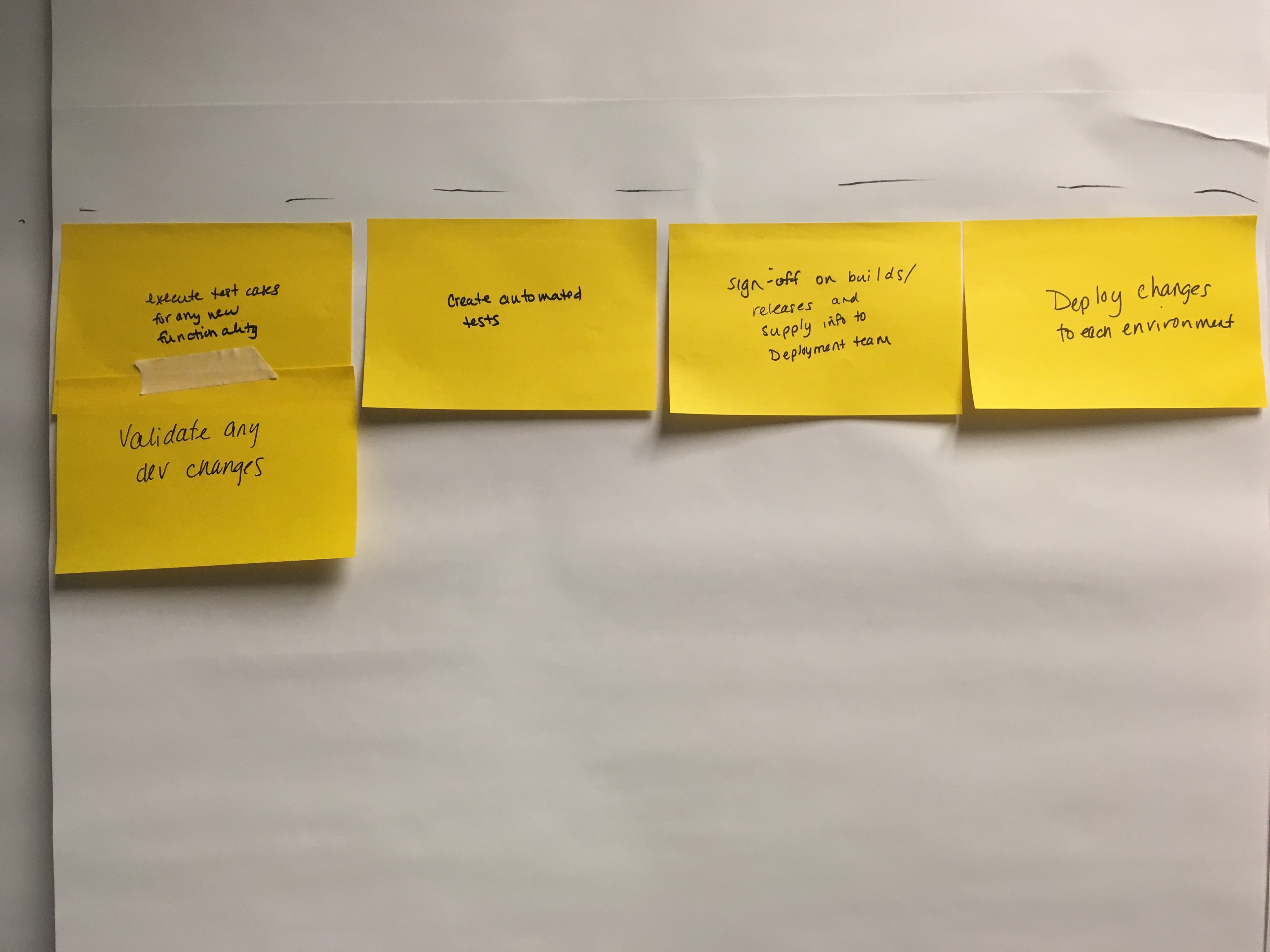

Automation was the solution needed, and to prove it, we made current state task models of the process. The development of the current state task models took longer than expected. We learned that client relations team played a larger role than anyone thought. Another huge finding was that everyone was managing statuses through shared excel sheets. Managing the certification and validation statuses through shared excel sheets was chaotic and would only get worse if another manufacturer program got added. The current state task models helped the RSC Lead prove to the Product Owner that focusing on automation instead of the new checks would be a more valuable use of resources.